Specialized Coatings & Materials Development

Advanced Manufacturing Return to Livermore Laboratories Home

Advanced Materials Development

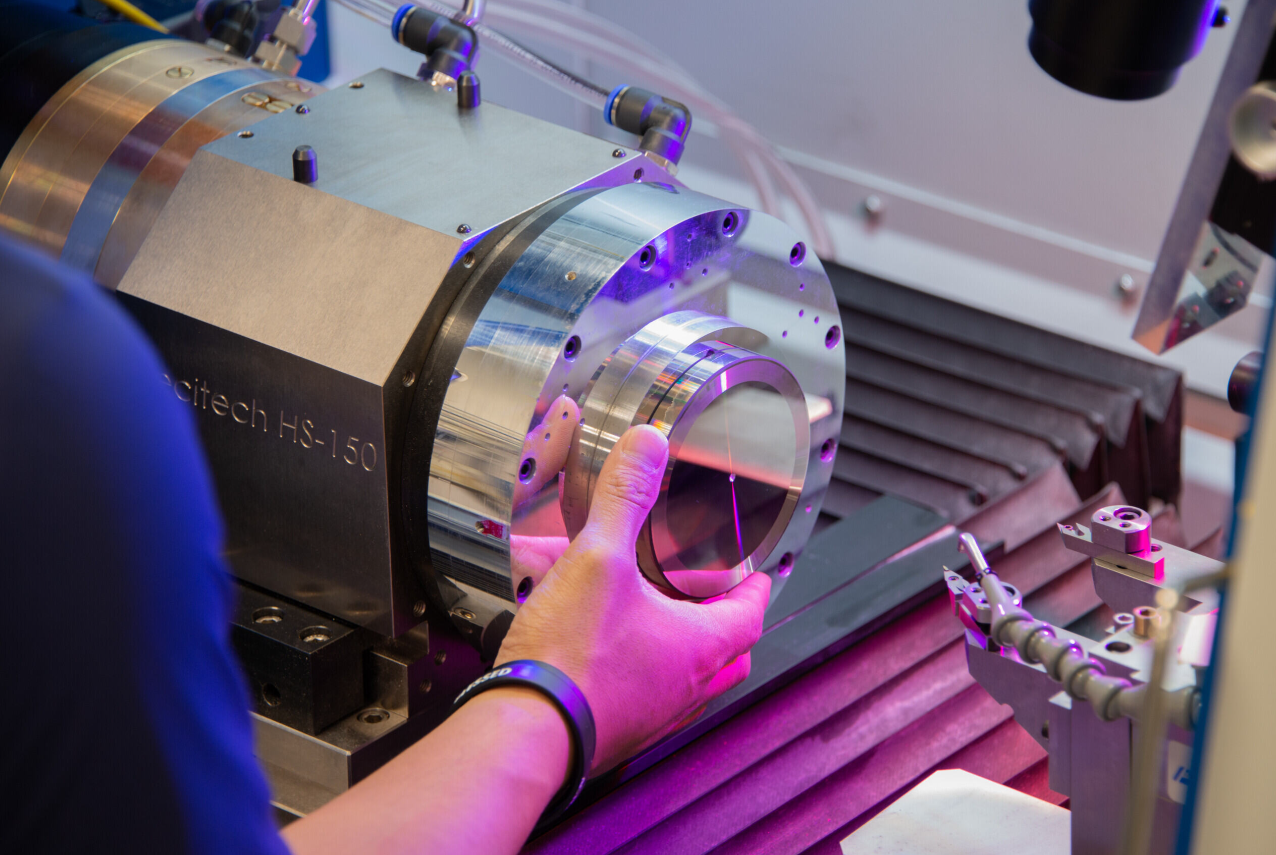

With MANTECH’s state-of-the-art diamond turning lathes and precision mills, our highly skilled staff machines custom structures in sizes from 10s of centimeters to sub-millimeter. Our team achieves precision and tolerances at the micron-to-nanometer levels. Components from metals, alloys, plastic and polymers are machined to exacting dimensions. A suite of high-precision metrology tools provides complete documentation of components’ as-built specifications.

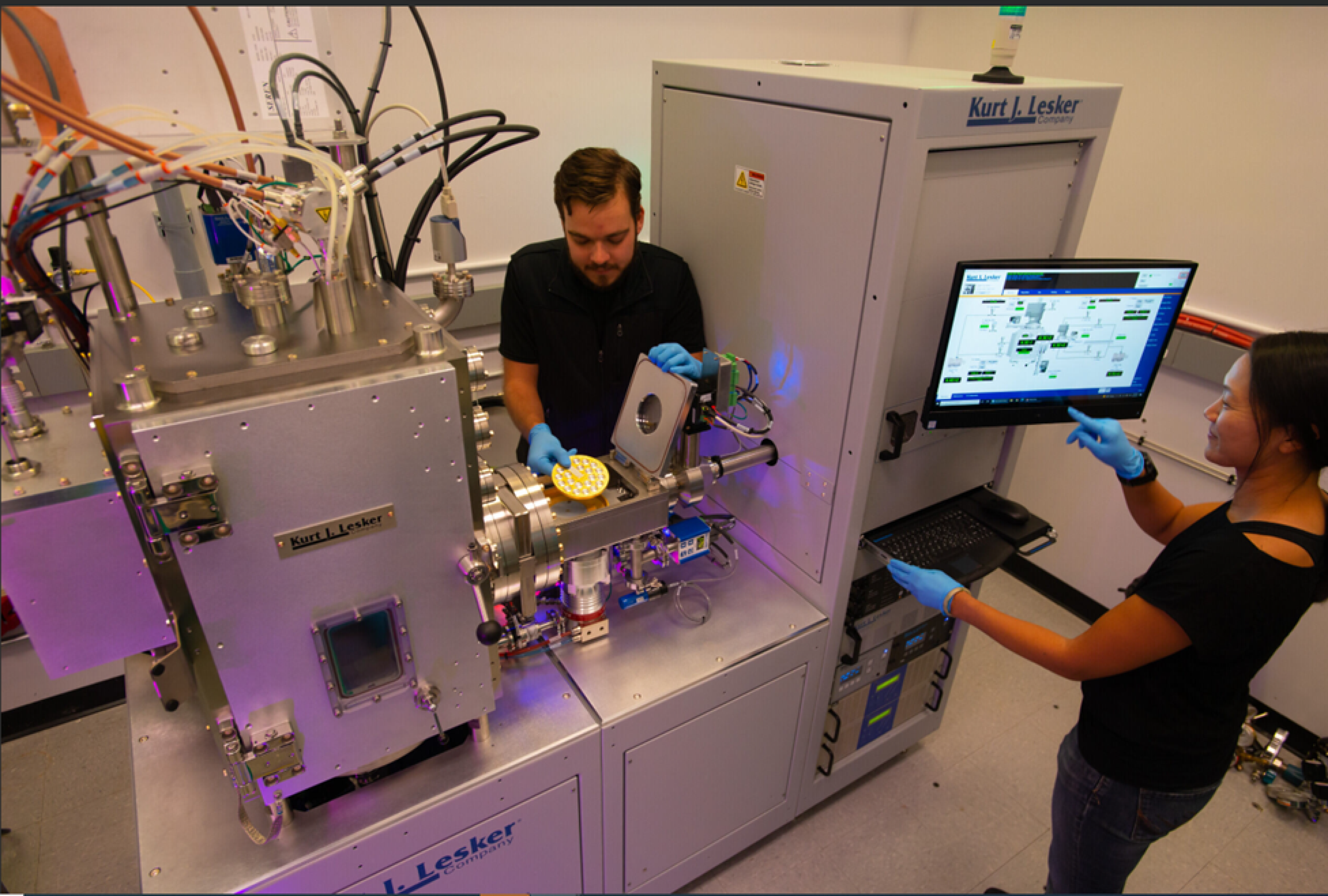

Coatings are applied to a wide variety of surfaces and complex geometries

- MANTECH designs and machines custom sample holders to enable coatings of a wide variety of surfaces and complex geometries

- MANTECH’s expertise in surface preparation is critical for good film adhesion

- Chemical surface treatment - Acid or base cleaning of surfaces

- Ex situ, in a plasma etcher, and in situ plasma etching in the deposition chamber

- Metals, oxides and nitride films are prepared by e-beam evaporation and sputter deposition

- Sputter coater is equipped with 3 targets for multilayer and elemental mixture depositions

- E-beam evaporator with four pockets for multilayers

- Single- and multi-layer anti-reflective coatings

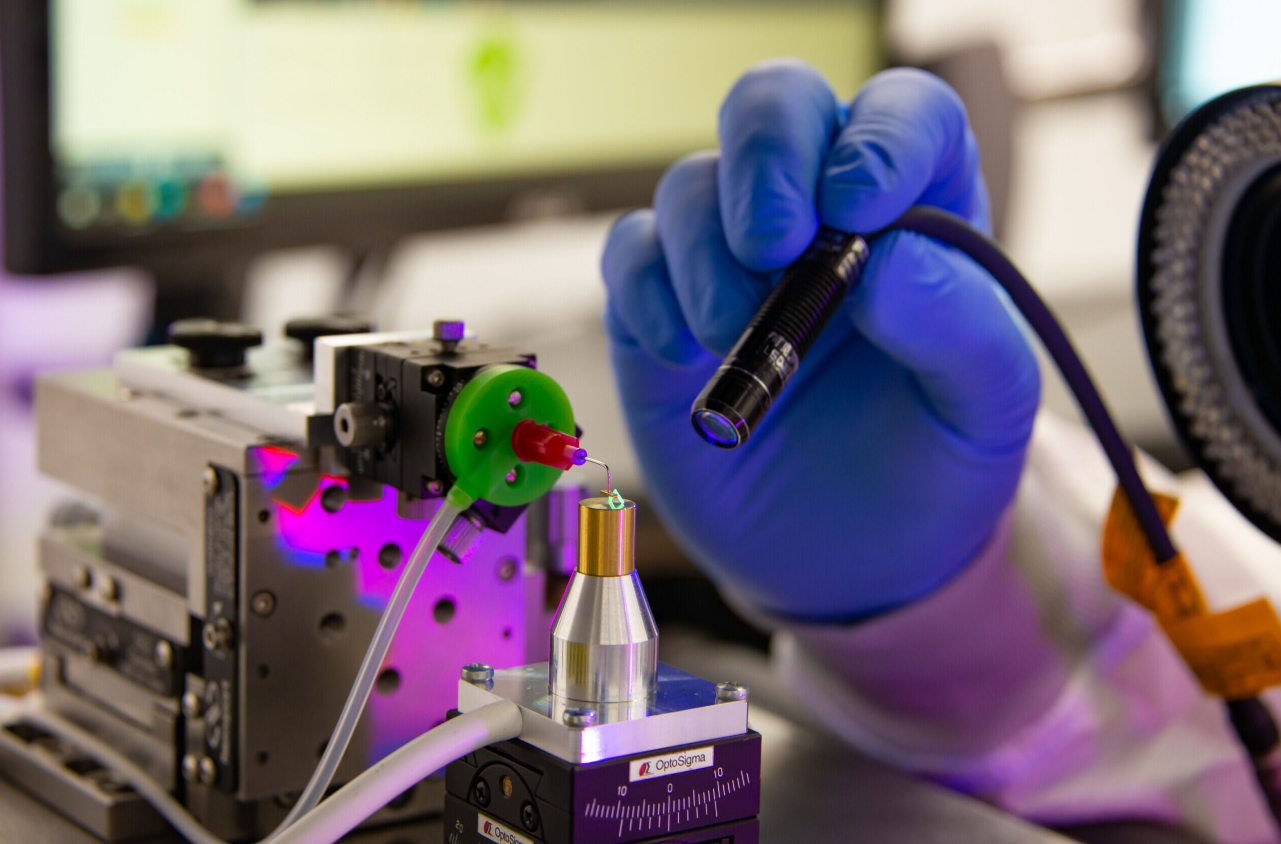

- Doped and undoped polymer films are deposited using plasma assisted chemical vapor deposition

- Spin coating and casting on substrates provides polymer solids and films up to one millimeter thickness

- Cast solid films can be formed with specified geometrical features

- Cast solid films can be formed with specified geometrical features

- Electroplating: Gold up to 100 microns thick electroplated onto conductive surfaces

- Bulk polymers can be synthesized in our chemical laboratory

- Low density solids synthesis using gelation and supercritical drying techniques

- Polymers with chemical dopants

Available Metals

MANTECH Livermore Laboratory’s versatile coating facility includes:

- E-beam evaporation and sputter deposition deposit thin layers of Au, Pd, Al, Cu, Mg, Fe, Gd, Si, Ni, Ti, Cr, and some non-metals onto target components. Quartz crystal monitors (QCM) are integrated into the coaters for in-situ monitoring of coating thickness, which provides nanometer level control.

- Electroplating station is used for gold plating, up to 10s of microns thick.