Metrology

Ensuring Dimensional Accuracy. Return to Livermore Laboratories Home

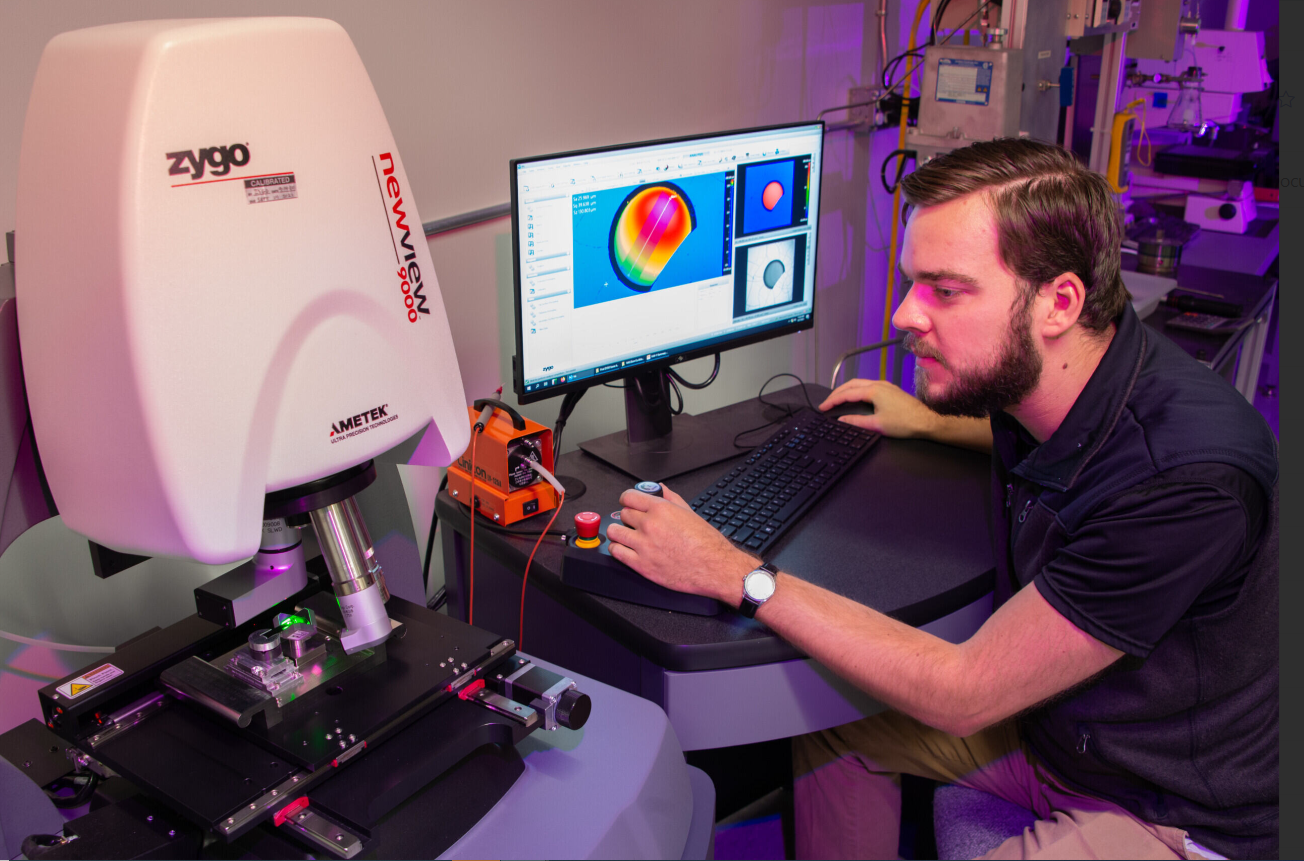

Precision Characterization & Metrology

With MANTECH’s state-of-the-art diamond turning lathes and precision mills, our highly skilled staff machines custom structures in sizes from 10s of centimeters to sub-millimeter. Our team achieves precision and tolerances at the micron-to-nanometer levels. Components from metals, alloys, plastic and polymers are machined to exacting dimensions. A suite of high-precision metrology tools provides complete documentation of components’ as-built specifications.

Featured Capabilities

- Visible and UV spectrometer for characterizing AR coatings

- 3-d morphology (dimensional and roughness)

- White-light interferometry

- Confocal microscopy

- Stylus profilometry

- Optical measuring microscopy

- Scanning Electron Microscopy

Major Fabricator of Targets for DOE Laboratories

Over three decades, MANTECH Livermore Laboratory has developed and refined techniques in target fabrication for the Department of Energy’s Inertial Confined Fusion, High Energy Density, and basic science programs. These efforts are prompted by evolving needs of our customers for new target types or tighter specifications. The resulting developments in precision micromachining, fixturing, assembly, 2-photon direct-write polymerization, novel metallic and oxide coatings, high-strength and thin polyimide windows, are applied to provide targets to rigorous standards.

Capabilities applied to Target Fabrication comprise:

- Engineering Design

- Precision Machining- Diamond turning and milling

- Coatings: PVD, CVD, Electro-deposition

- Bonding components into final assemblies

Other Applications

- Microfluidics

- Medical devices

- Sensor technologies

- Microelectromechanical Systems (MEMS)

- Prototyping and development