Precision Machining

MANTECH Livermore Labs delivers nanometer-precision parts via advanced lathes, mills, and laser machining of diverse materials. Return to Livermore Laboratories Home

Precision Machining Capabilities

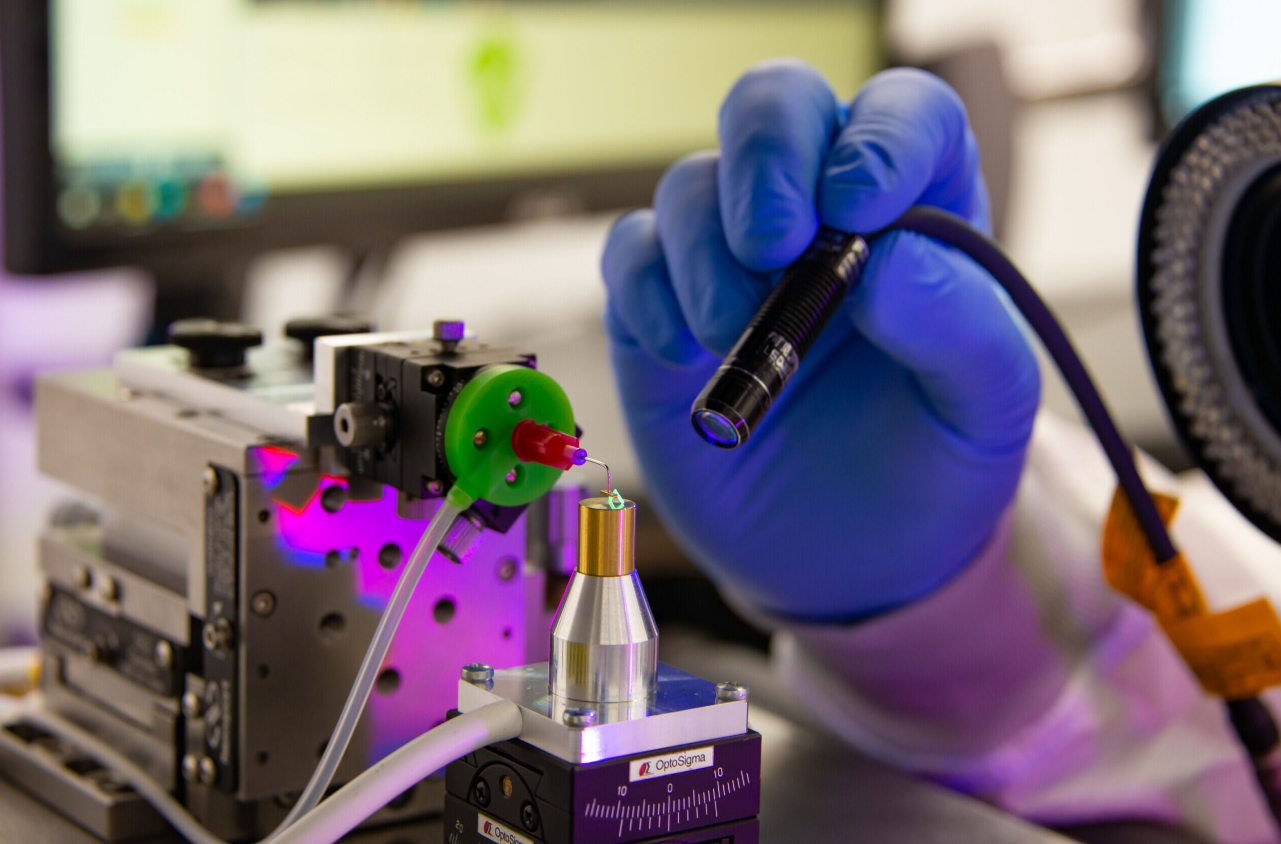

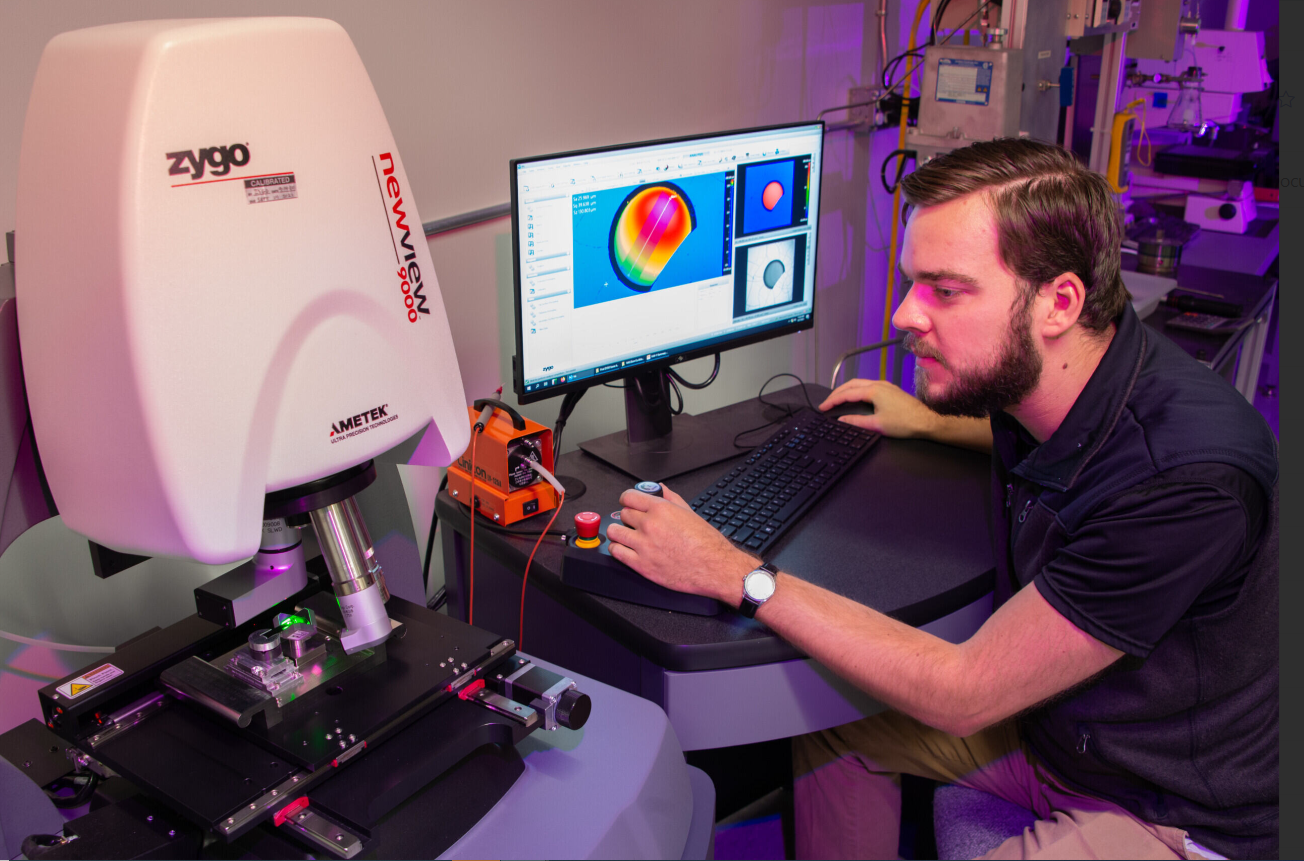

With MANTECH’s state-of-the-art diamond turning lathes and precision mills, our highly skilled staff machines custom structures in sizes from 10s of centimeters to sub-millimeter. Our team achieves precision and tolerances at the micron-to-nanometer levels. Components from metals, alloys, plastic and polymers are machined to exacting dimensions. A suite of high-precision metrology tools provides complete documentation of components’ as-built specifications.

Equipment, tolerances, and materials

A wide variety of materials (metals, plastics, low density aerogels and carbons), shapes, and dimensions can be machined with specified features.

- Diamond turning lathes provide sub-micron features with 10 nm resolution and surfaces smooth to 5-10 nm RMS. Parts with dimensions from 100 microns to 20 cm in length and width can be machined.

- 5 and 3 axis mills achieve 1 μm dimensional tolerance on components up to 20 cm in size.

- Conventional CNC machines fabricate parts with micron tolerances

- Laser machining is used for cutting and engraving